One of SAP’s most powerful features is its flexible SAP organizational structures that can be tailored to meet a company’s unique procurement needs. Whether your enterprise is operating across multiple plants, company codes, or regions, SAP allows you to structure purchasing processes in a way that aligns with your business operations.

Here we explore five core SAP organizational structures that demonstrate how organizations can configure SAP to streamline procurement using SAP MM (Materials Management) best practices.

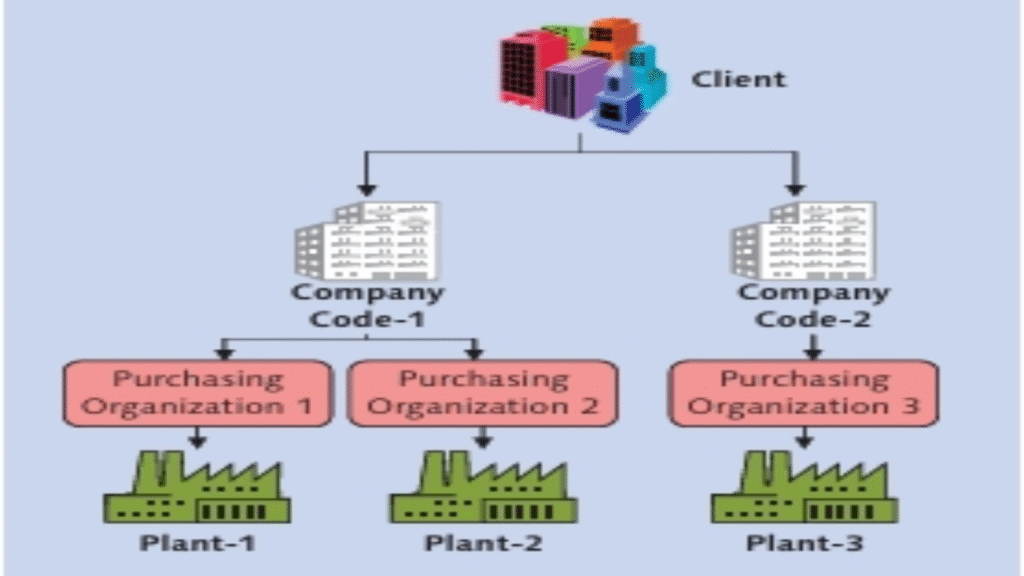

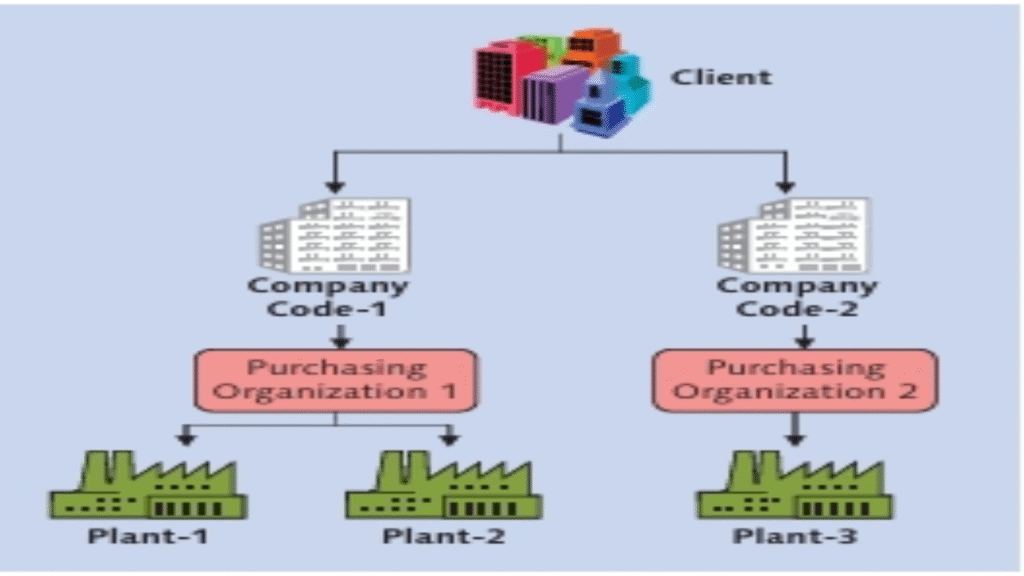

1 Plant-Specific Purchasing Organization

In this scenario, each plant has its own purchasing department that handles everything from vendor negotiations to purchase order processing. This is ideal for companies where each plant operates independently or serves unique market needs.

For example, if your business has three plants across two company codes, each plant will have its own purchasing organization in SAP. These purchasing organizations are directly assigned to their respective plants, ensuring full control over procurement at the plant level.

Benefits:

- Autonomy for each plant’s procurement team

- More targeted vendor relationships

- Clear accountability and reporting

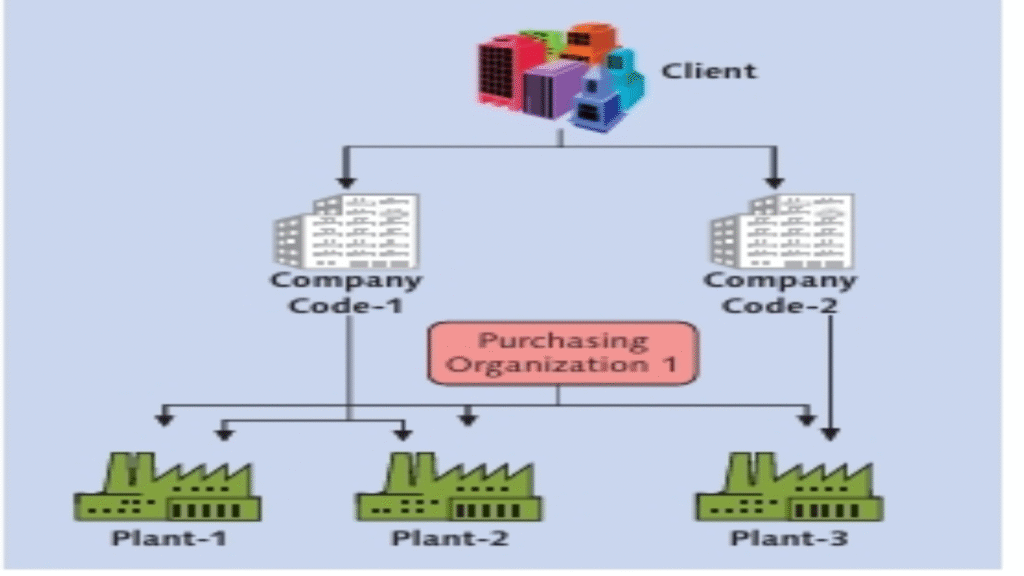

2 Cross-Plant Purchasing Within a Company Code

This model is perfect when a single purchasing team handles procurement for multiple plants under the same company code. The cross-plant purchasing organization reduces duplication and consolidates efforts across plants, improving efficiency.

A real-world example might be a national airline headquartered in Mumbai. With several regional airports (treated as plants), the company uses a single purchasing organization to procure goods and services across all airports.

Advantages:

- Centralized procurement operations

- Standardized purchasing policies

- Better volume discounts and pricing

3 Cross-Company Code Purchasing

Organizations operating in multiple legal entities (company codes) may still wish to centralize purchasing operations. In the cross-company code purchasing scenario, one purchasing organization manages procurement for multiple plants across different company codes.

A global paper manufacturer with 15 legal entities and 50 plants can benefit from this model. One centralized purchasing team handles all vendor negotiations and manages long-term contracts, streamlining procurement on a global scale.

Highlights:

- Increased negotiation power through volume buying

- Simplified vendor management

- Easier contract lifecycle tracking

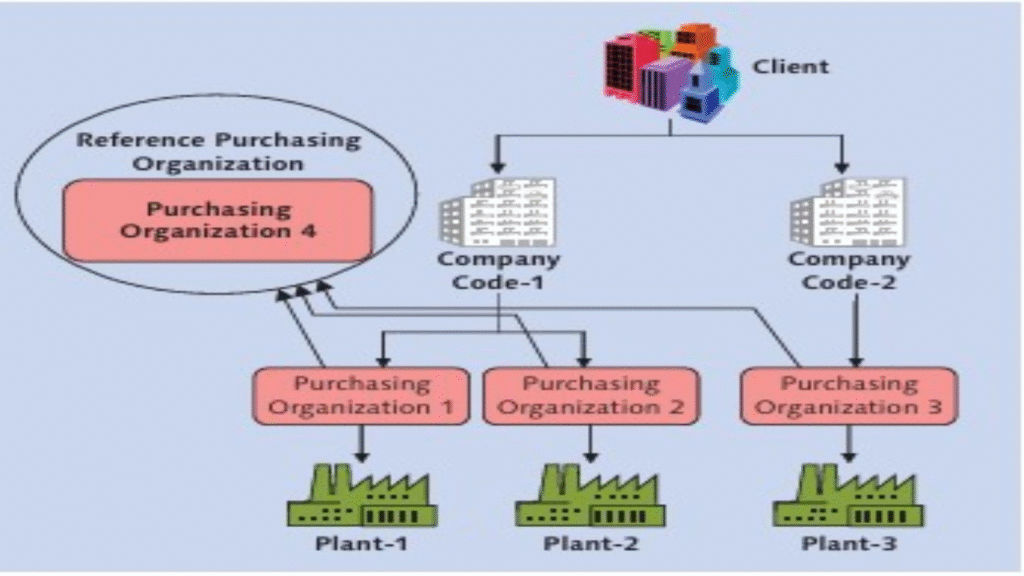

4 Reference Purchasing Organization

Some companies prefer a hybrid structure: global agreements negotiated at the corporate level, with local purchasing teams executing the actual orders. This is where the reference purchasing organization model fits.

A designated reference purchasing org handles supplier negotiations and creates global outline agreements. Local purchasing organizations (at plant or company level) can create purchase orders referencing those master agreements.

Ideal for:

- Large enterprises with distributed operations

- Businesses looking to balance local autonomy with global efficiency

- Organizations aiming to optimize pricing at scale

5 Standard Purchasing Organization for Automation

SAP supports automatic purchase order creation, and this is where a standard purchasing organization comes in. Assigned at the plant level, it allows the system to automatically determine which purchasing org to use based on the requisition’s plant code.

This setup is useful for high-volume, repetitive procurement where automation can save time and reduce human errors.

Key Benefits:

- Automation-ready

- Faster purchase order processing

- Reduced manual workload

Final Thoughts

Choosing the right SAP organizational structure for procurement is essential for driving efficiency, governance, and cost savings. Whether your business needs plant-specific control or group-wide integration, SAP provides the flexibility to match your operational strategy.

Understanding these business scenarios helps implementation teams configure SAP MM effectively and ensure long-term procurement success.

Choosing the Right Structure for Your Business

Selecting the most suitable purchasing structure in SAP isn’t a one-size-fits-all decision—it depends on your organization’s size, geographic distribution, product lines, and operational complexity. During SAP implementation or redesign, it’s crucial to analyze procurement workflows, vendor interactions, and compliance needs to determine whether a centralized, decentralized, or hybrid purchasing model aligns best with your strategic goals. A well-structured SAP organizational setup not only enhances procurement efficiency but also supports long-term scalability and audit readiness.